Hardness Testers

The process of hardness testing is covered by a number of hardness scales, the most common being: Knoop, Vickers, Rockwell and Brinell. These tests are used to identify the correct material to be used in a particular project. The tests provide a ‘hardness’ value for the chosen material which will indicate if its durability properties will be suitable for the intended purpose.

Test procedure

The hardness of a material is usually indicated by the level of penetration into the material when struck by either a pointed or rounded diamond, carbide or hardened steel indenter. The material used in the indenter will always be harder than that of the material being tested.

Types of test

The Brinell test is the oldest of the hardness testers in use today and dates back to the early twentieth century. It is still used in finding the hardness of forged and cast materials and for quality control purposes. The Vickers test was introduced around twenty-five years after the Brinell test. It is considered to be the easiest test method to use. The Rockwell test is used around the world and is suitable for the majority of types of metal and also some plastics. Finally, the Knoop test is considered to be more suitable for testing small areas of material.

Universal machines

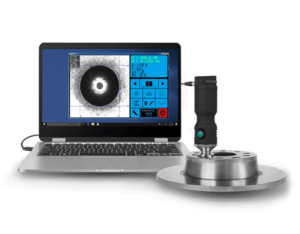

Hardness testers are available which are designed to be able to perform all of the above named tasks.